Tested. Proven. Trusted.

Safety. Reliability. Protection. Confidence. These are the promises ArmorSource aims to deliver. In an ongoing effort to improve the quality and safety of our products, and to ensure the development of new technologies ArmorSource leverages our on-site, state-of-the-art ballistic and non-ballistic testing labs to deliver convenient, time-sensitive testing against various ballistic, environmental, and mechanical requirements.

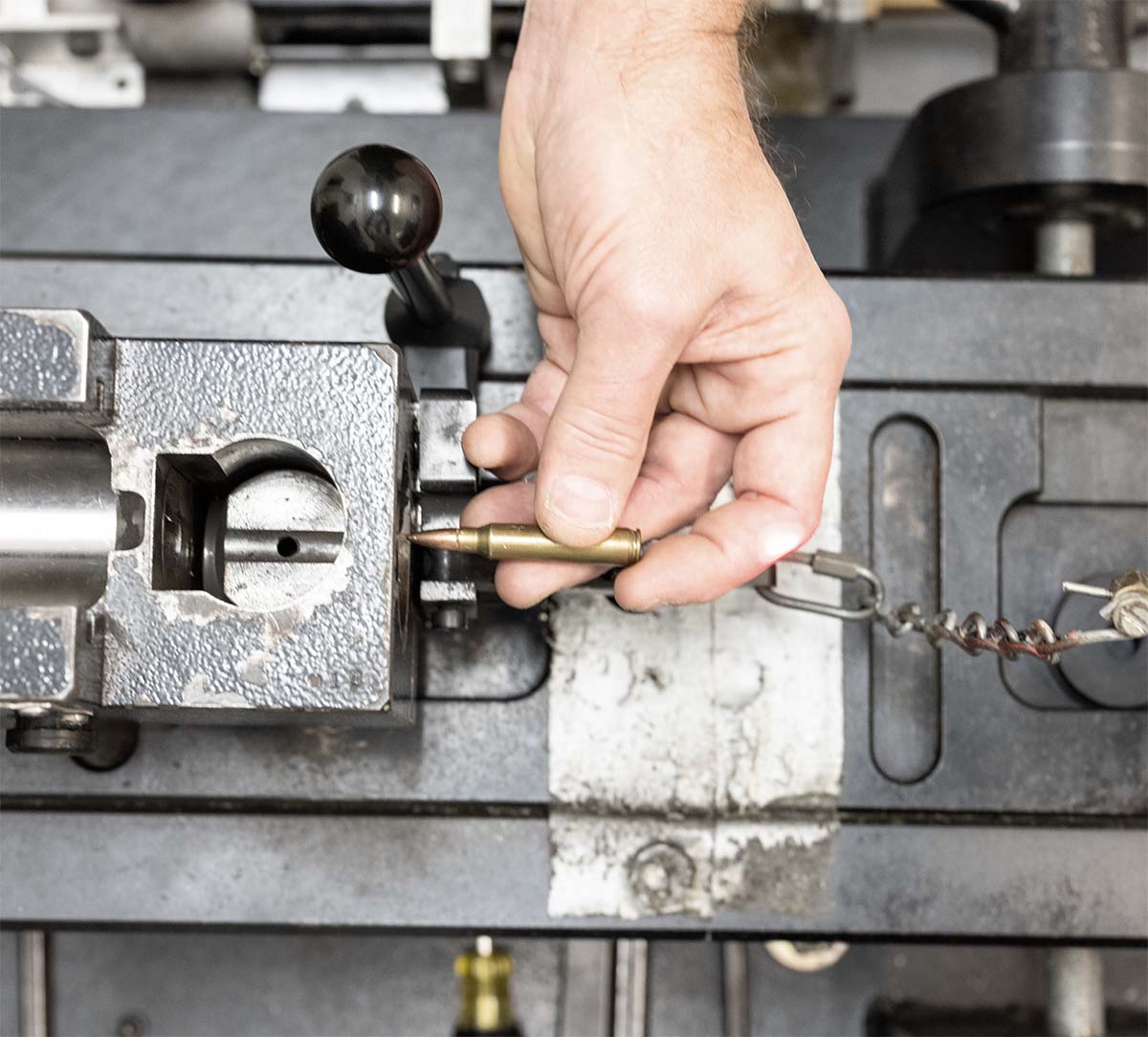

Our testing labs replicate real-life threats, similar testing facilities and methods of our customers, and meet the standard requirements set for independent commercial labs. Our ballistic range provides a safe and controlled environment for testing handguns, fragments (Right Circular Cylinder, Fragment Simulating Projectiles – 2, 4 ,16, 64, 17 grain), small arms (rifles), and back-face deformation (trauma).

Additionally, our in-house testing capabilities include environmental and mechanical testing which allows us to evaluate and deliver optimal performance characteristics, such as blunt impact, compression resistance, impact resistance, helmet stability and additional safety features for every helmet we produce.

To support the most demanding users on the planet and to ensure confidence in product, our quality assurance team leverages state of the art testing capabilities to ensure that every product that leaves our doors will meet or exceed required performance metrics.